Metalworking tools

-

Turning

-

Milling

-

Drilling

-

Thread cutting

-

Reaming and drilling

-

Countersinking and needling

-

Broaching

-

Yours - thermdrill

-

Welding

-

Grinding, cutting and polishing of metal

-

Stretching and extrusion

-

Řezné oleje, tuky a odlučovače

-

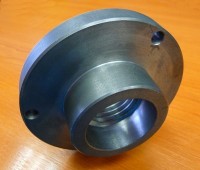

Flange for lathe MN80, dia. 100mm for universal chuck, semi-finished product

Semi-finished flange for clamping universal chuck, for lathe MN 80 Diameter of flange: 100mm Flange is without machined mounting and without holes for chuck clamping. A chuck of any brand/manufacturer can be clamped onto this flange after its additional modification. Material: Steel Thread: M 39Af4

On request86,72 € with VAT -

Flange for lathe MN80, dia. 125mm for universal chuck, blank

Semi-finished flange for clamping the universal chuck, for lathe MN 80 Diameter of the flange: 125mm The flange is without a machined fitting and without holes for clamping the chuck. A chuck of any brand/manufacturer can be clamped onto this flange after its additional modification. Material: Steel Thread: M 39Af4

In stock102,49 € with VAT -

Improved feed shaft gear for MN80 lathe

Improved gear wheel - accommodation of the shift shaft Compared to the original gear wheel, which was supplied with the MN80 lathes, this one also has an encapsulated opening with sliding bronze, which is pressed there under enormous pressure. Attention - two types were used for the MN80 lathe: 1. Gear wheel with a cylindrical diameter of 30 mm and a length of 22 mm (the same diameter as the hole in the lyre) 2. Gear wheel with a cylindrical diameter to press 30mm in a length of 14mm and a setting of 32mm in a length of 8mm (the lyre has a hole with a diameter of 32mm) If you need type 2 with mounting, please add this to the order notes. The gearing is very precisely rolled. All sanded.

In stock129,95 € with VAT -

Improved feed shaft gear for MN80 lathe

Improved gear wheel - accommodation of the shift shaft Compared to the original gear wheel, which was supplied with the MN80 lathes, this one also has an encapsulated opening with sliding bronze, which is pressed there under enormous pressure. Attention - two types were used for the MN80 lathe: 1. Gear wheel with a cylindrical diameter of 30 mm and a length of 22 mm (the same diameter as the hole in the lyre) 2. Gear wheel with a cylindrical diameter to press 30mm in a length of 14mm and a setting of 32mm in a length of 8mm (the lyre has a hole with a diameter of 32mm) If you need type 2 with mounting, please add this to the order notes. The gearing is very precisely rolled. All sanded.

In stock129,95 € with VAT -

Improved vernier of longitudinal feed with measuring, for MN80 lathe

PROFI set for measuring the displacement of the main support for the MN80 lathe with an adjustable scale - vernier / with an adjustable zero - quick setting The small gear in the photo is now newly supplied without a drilled hole - these diameters were machined differently on the MN80 lathes - therefore we recommend finishing it as needed and securing it with a suitable locking pin (locking pin not included). Compared to the original, the set has an adjustable vernier - the possibility of setting zero as needed + locking with a threaded screw in the front of the wheel. One part = 0.1mm Turn of the main wheel = 24mm Nonius has 240 parts on a diameter of 61mm, where the gap between the parts is 0.8mm and one part means 0.1mm of displacement. The description is from number 0 to 23 mm, a total of 24 mm per turn in the upward direction of rotation. Eccentric bushings replace the original metal bushings for the gear shaft with the main handwheel, and the front bushing also serves as a vernier counter plate. Eccentric bushings are encased in bronze. The entire assembly is only 10mm longer than the original variant, and that is by the strength of the nonia counter plate. The diameter of the hand wheel is the same as the original, but the wheel is much more massive. The whole set has a massive impression and, thanks to the chosen materials, is also very rigid compared to Chinese plastic handwheels. Exchange : Replacement can be done only for the price of removing the support box practically only with a drill and M4 and M5 taps. See the attached instructions for more.

On request321,07 € with VAT -

Basic wheel 30z for thread cutting for MN80 lathe

Basic gear 30z for MN 80 lathe, including pen Suitable for thread cutting when the value of the replaceable sprocket at the position of the wheel A is not 20 teeth and therefore does not use the basic toothed wheelset 30 / 20 teeth. In this particular case, we must use this gear with a pin and a pin to install any toothed wheel A in the assembly with this wheel as a basis for assembling the gear. This toothed wheel serves as a tray for wheel A, which is mounted on the shoulder. Conversion continues with wheels B and C, which are firmly connected together with the Bronze Clutch and followed by wheel D. The gearwheel is attached to the upper fixed pin of the lyre under the sprockets the speed of the feed screw. In the basic assembly, the toothed wheel 30 / 20z operates in one piece, since the tooth exchange gear 20 has a hole 14H7 and a groove at a depth of 2 mm unmanufactured. if necessary, cutting a thread whose pitch requires a different number of teeth than 20, the wheel shown as a base for the wheel A of the gear set must be installed on the base pin. This part is made with a precise hole 10H7 without bronzing, since it is mainly used for cutting threads at low speeds and therefore does not fulfill the function of the shift wheel in both conventional and high-speed turning. Material: 12,050 (C45), toothed with precision on a precise mandrel with minimal run-out. The ball is of course a pen that is not in the pictures. Everything is also grounded.

In stock68,80 € with VAT -

Hydraulic protective oil Nuto H 68, Mobil, 1 liter

Volume: 1 liter Packaging: In a plastic container / bottle with lid (non-original bottle - spilled) High quality hydraulic oil with wear protection Classification and Specifications: br> AFNOR NF-E 48-690 / 1 AFNOR NF-E 48-603 HM Denison HF-0 Vickers I-286-S Vickers M-2950-S DIN 51524 Part 2 - HLP - ISO 11158 - Type HM Approvals: Denison HF-0 Cincinnati Machine P-69 Characteristics: viscosity grade ISO: 68 Viscosity, ASTM D 445, at 40 ° C: 68 Viscosity, ASTM D 445, at 100 ° C: 8.5 Viscosity Index, ASTM D 2270: 107 Corrosion Copper Strip, ASTM D 130: 1A Corrosion Protection, ASTM D 665B: Meets Pour Point, ° C, ASTM D 97: -18 Flash Point, ° C, ASTM D92: 234 Density at 15 ° C, ASTM D 1298, kg / l: 0,882 Deemulsation time (minutes) over 3ml emulsion at 54 ° C: 20 Description: Determination of industrial and mobile wagon applications that require wear-resistant oils. By combining high quality base oils and a selected combination of additives, a product has been developed that meets many of the demanding parameters necessary to increase performance and extend the life of the device. Nuto H Series Oils deliver good performance in a wide range of hydraulic system components that are subject to mild to very demanding operating conditions. High resistance to oxidation and chemical stability help to regulate the formation of sediments and reduce the risk of valve leaks, resulting in reduced hydraulic performance. Oils have an extended service life and are very well filterable, thus reducing maintenance costs. They provide good corrosion protection in humid environments, easy to remove water, and have a good air separation capability. Products meet the requirements of a number of Aut

In stock6,82 € with VAT